Rebar Shop Drawings

Rebar Detail Drawing Provider

Detailed and accurate rebar shop drawings service provider. We have years of experience creating rebar shop drawings. Fill this form for quote.

Let's Dive Into Rebar Shop Drawings

OUR HISTORY: We started providing rebar shop drawings and specialized rebar detailing and estimating services to contractors and rebar suppliers in the tri-state area (New York, New Jersey, and Connecticut) – later on, we expanded nationwide. We have a team of professional rebar detailers and estimators equipped with industry experience and modern & sophisticated technology.

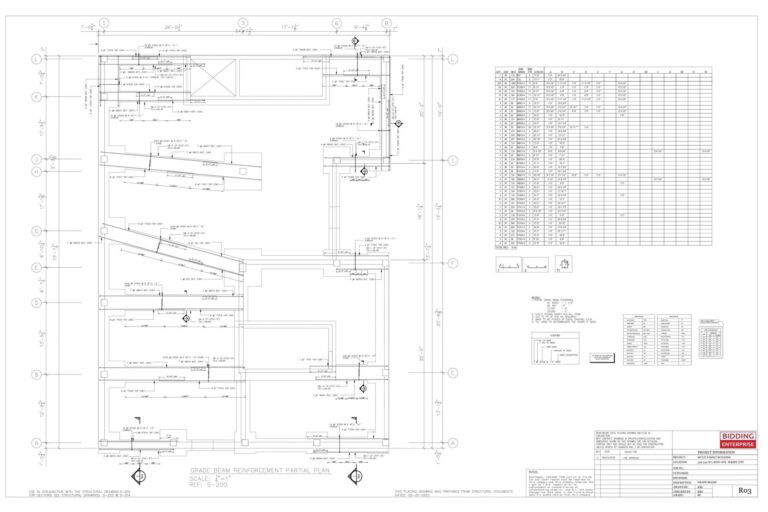

WHO IS IT FOR? Rebar Detailing & shop drawings enlist rebar placement and reinforcement – the purpose of Rebar Detailing is to assist project managers and site superintendents in accurately supervising the rebar installation at the work site.

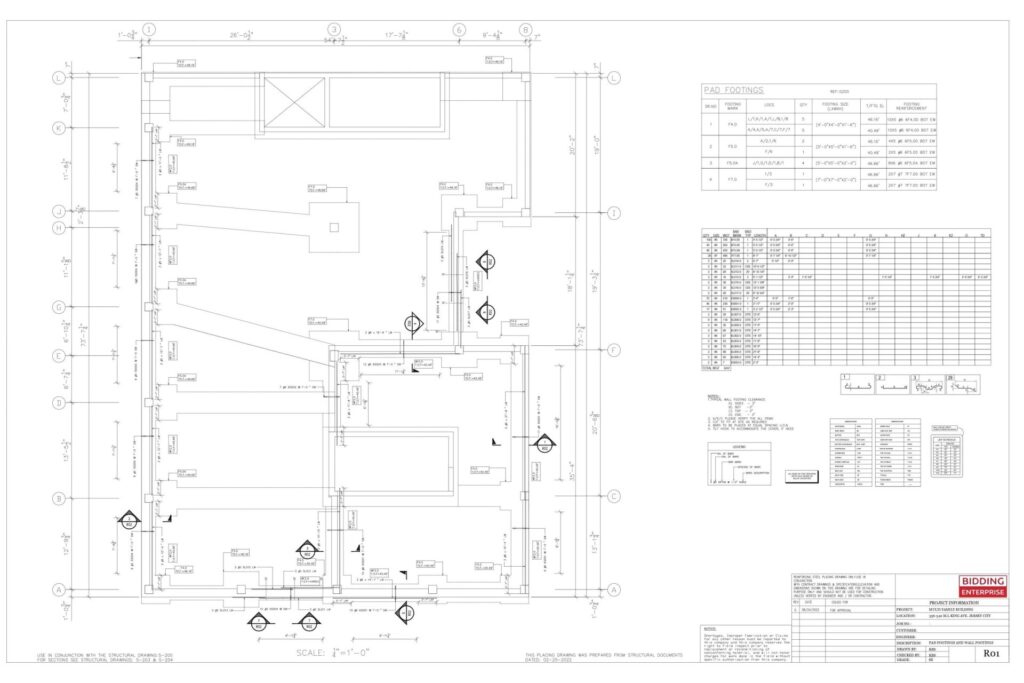

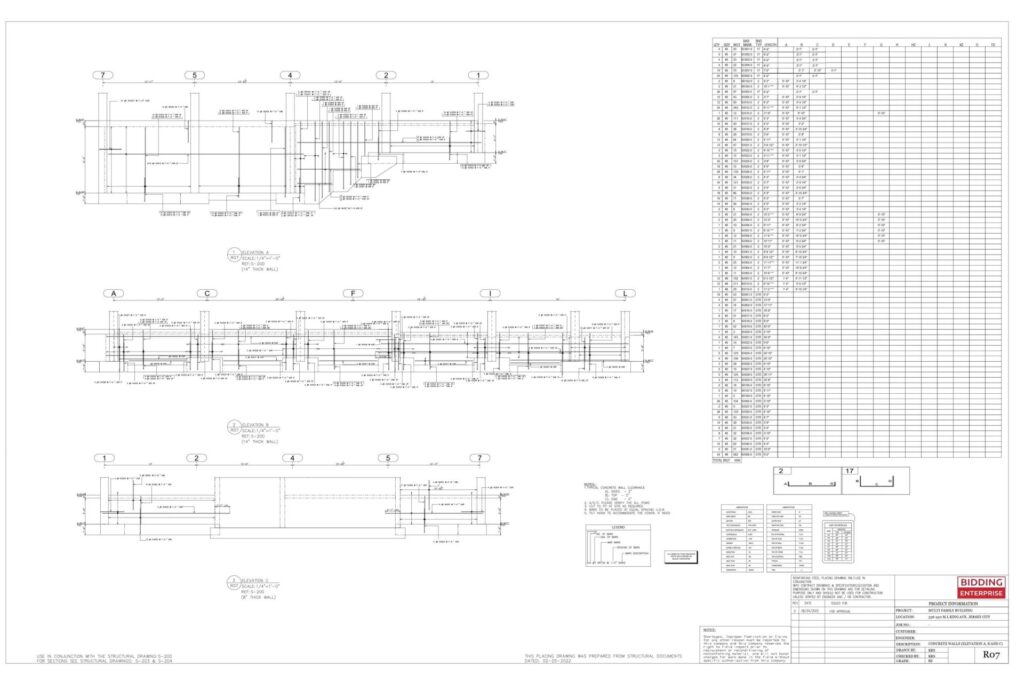

WHAT IS INCLUDED? The Rebar Detailing procedure integrates the position of bars also called rebar placements, bending schedule, numbers of rebar lengths, overlapping schedule, and more. Our rebar detailers prepare rebar detailing & rebar shop drawings to incorporate the spacing of bars, area, rebar size (thickness), and lap of steel. This information needs to be accurate to a fraction of inches.

How Rebar shop drawings are used in the field

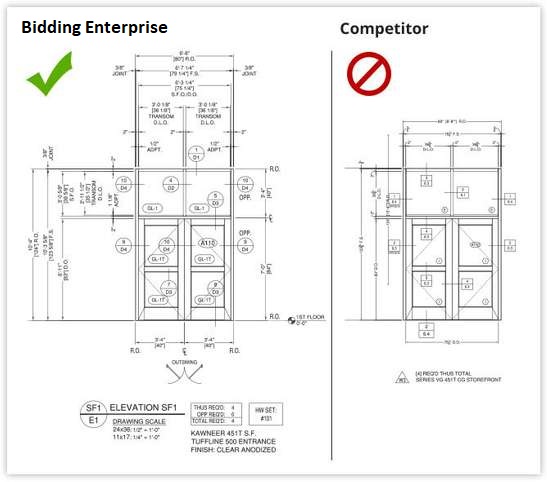

The crew on the site heavily depends on shop drawings for rebar placement. These drawings help the supervisors to ensure that the structural design is properly executed in the field. Rebar shop drawings show each and every piece of rebar thus maximize the productivity, minimize quality issues and these are a great way to communicate between the structural engineer & the concrete contractor. The rebar shop drawings are also used a tool for takeoffs. Quantities are calculated from these lines by making the bar bending schedules.

The structural drawings are usually created by the engineers mainly concerned about the stability of the structure. This makes the structural drawings a bit confusing for the operations on the site.

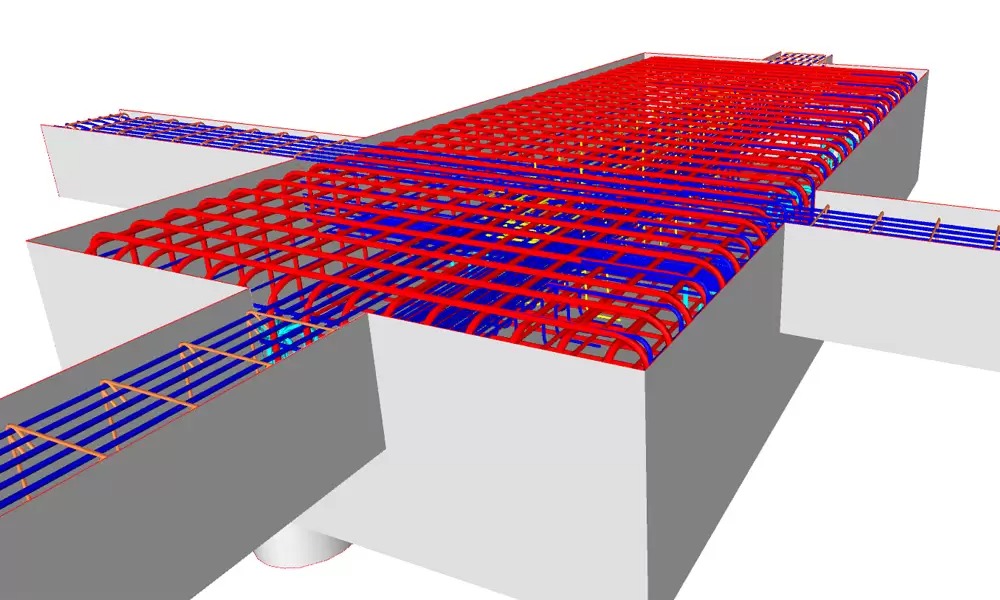

To avoid any sort of confusion and to ensure smooth rebar placement, the industry is adopting to 3D modeling of the rebar. These 3D models are prepared using different software which enables the site crew as well as the structural designer to locate any piece of bar easily. Rebar 2D and 3D modeling enables the quantity surveyor / estimator to meet the estimating needs of the project.

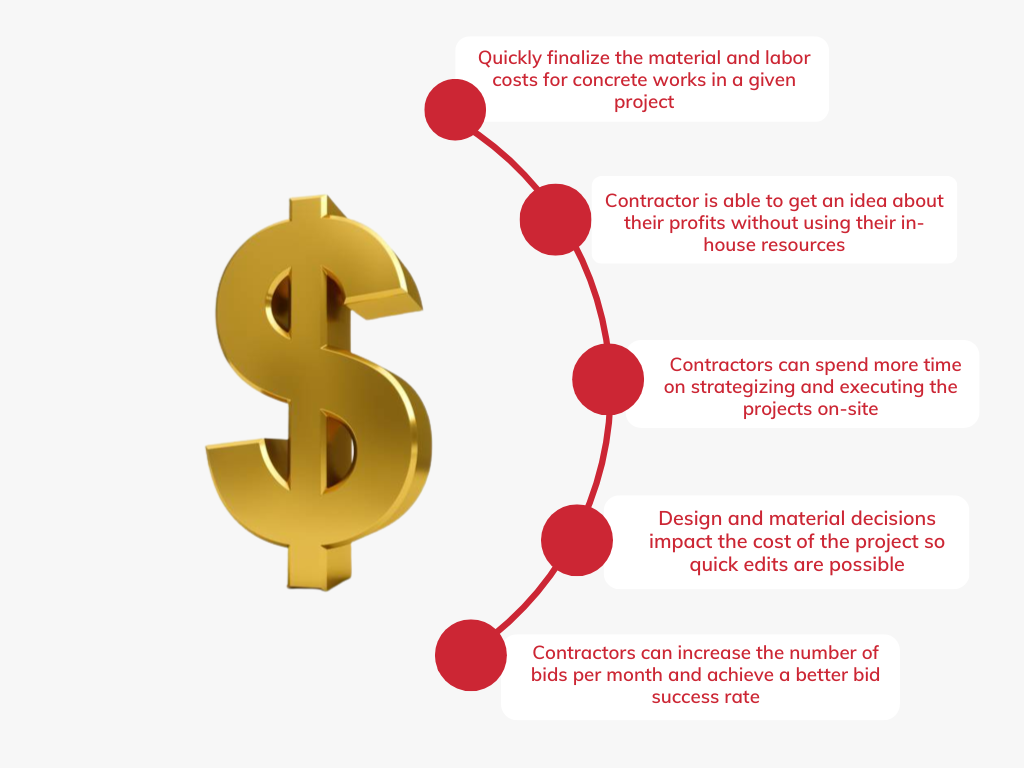

Real cost of not getting accurate Rebar shop drawings

Preparing rebar shop drawings is time taking and requires skills and resources. It may be tempting not to get the rebar shop drawings prepared, but sometimes penny-wise can cost you a dollar. Every sophisticated project requires rebar shop drawings to uphold quality standards. More and more stakeholders understand this, and therefore, the companies have started to prepare rebar shop drawings even for smaller projects to achieve efficiency in the operations of the construction project. More often than not, the project managers make this a mandatory step to achieve their goals.

Not getting the rebar shop drawings in time or getting them wrong can be a huge cost impact on the construction project. It results in otherwise easily avoidable delays, compromise of the structural strength of the project, cost overruns, and waste of material due to mismanagement.

- Delays in getting material:

If we do not have the rebar shop drawings wherein we are unable to develop the weight table as well as the bar list then the material procurement will be delayed as no one will exactly know which # of bars are required in what quantities. The shop drawings will be divided into logical sections like footings, foundation walls, Slab on Grade, columns, beams, shear walls etc. thus streamlining the procurement and rebar placement.

- Delay in the Projects:

The delayed rebar shop drawings are often responsible for delay in the construction activities. Ultimately the critical activities will be delayed which will ultimately delay the overall project in terms of Cost as well as in terms of Schedule.

- Failed Inspections:

Rebar placement requires inspection and when the rebar shop drawings are not available, then the inspection cannot be commenced in time. This brings a bad repute to the concrete contractors and can result in a conflict between the stakeholders involved.

What We Do – As A Rebar Detailer

Here at Bidding Enterprise, our team of skilled rebar detailers prepares rebar shop drawings for the placement of the reinforcing steel. We provide precise details on bends, shapes, and lap splices to meet the requirement of your specific project. Any issues regarding project constructability are tackled instantly before the first piece of rebar is bent or sheered. The detailed drawings provided by our rebar detailers often help our contractors to visualize the structures. In fact, with these detailed drawings, the task of ironworkers is highly simplified, as they know where to place and thus reduce the cost of installation.

Rebar Shop Drawings

your team can trust

- Rebar placement drawings

- Bar Bending Schedule – ASA Format

- Weight & Change Order Tracking

- 2D & 3D structures

- Rebar Takeoffs

How Bidding Enterprise can Help

Bidding Enterprise provides the solution for all the steel rebar shop drawings and rebar 2D and 3D modeling in a way where it can be assured that your structure is in our hands and the responsibility of being the provider of the most competent and skilled efforts among all. The Bidding Enterprise also provides the best estimation solutions.

As it is common saying “understanding the problem solves the 80% of the problem” and Bidding enterprise is focusing on this by providing such solutions which are never being managed by anyone with this excellence and skillset.

Our Rebar Shop Drawing Services Include

3D Rebar Detailing Services

Rebar Drawings and Schedule Services

Rebar Estimation Services

Key Features

Itemized List Of Quantities

Specialized Software

Affordable Rates

VALUE ADDED SERVICES AT NO ADDITIONAL COST

Color Coded Marked Plans

Collaboration Portal

Relationship Manager

Getting Started

1) Email us your project plans

2) Receive Our affordable Quote

3) We Prepare Estimate & Deliver to you

rebar Shop Drawing | FAQs

What is rebar?

What are standard rebar sizes?

For the imperial-unit countries, bar sizes give the diameter in units of the ⅛ inch for bar sizes #2 through #8. For example, 8⁄8 = #8 = 1 inch diameter. Equivalent metric size is typically specified as the nominal diameter rounded to the nearest millimeter. These sizes are not considered as standard metric sizes – they are considered soft conversion or the soft metric size. Imperial sizes system recognizes true metric bar sizes (No. 10, 12, 16, 20, 25, 28, 32, 36, 40, 50 and 60). That indicates the nominal bar diameter in millimeters.

See table below

| Imperial bar size | Metric bar size (soft) | Nominal diameter (in) | Nominal diameter (mm) |

|---|---|---|---|

| #2 | No.6 | 0.250 = 1⁄4 | 6.35 |

| #3 | No.10 | 0.375 = 3⁄8 | 9.525 |

| #4 | No.13 | 0.500 = 1⁄2 | 12.7 |

| #5 | No.16 | 0.625 = 5⁄8 | 15.875 |

| #6 | No.19 | 0.750 = 3⁄4 | 19.05 |

| #7 | No.22 | 0.875 = 7⁄8 | 22.225 |

| #8 | No.25 | 1.000 = 8⁄8 | 25.4 |

| #9 | No.29 | 1.128 ≈ 9⁄8 | 28.65 |

| #10 | No.32 | 1.270 ≈ 10⁄8 | 32.26 |

| #11 | No.36 | 1.410 ≈ 11⁄8 | 35.81 |

| #14 | No.43 | 1.693 ≈ 14⁄8 | 43 |

| #18 | No.57 | 2.257 ≈ 18⁄8 | 57.3 |

How to calculate the rebar cost for my project?

- Define the total length of rebar you will use in your slab.

- Multiply it by the price per meter of your chosen rebar diameter — now you have the total rebar cost.

- You can also use the rebar calculator on the Omnicalculator website to verify your findings.

How to calculate a rebar weight?

- If it is standardized rebar, find the manufacturing code and check its density.

- With the length (

ℓ) and diameter (d) of the rebar, calculate the rebar volume:(3.14 × d² / 4) × ℓ. - Multiply the volume per the material density. Now, you have the rebar weight.

Do I need rebar for my patio?

Not necessarily. When you expect heavy loads on the surface, you will require rebar because the weight will cause concrete to experiment tension stress. However, we always recommend you to check with a specialist.

Should I weld rebar?

You should avoid welding rebar. Instead, you should use a steel wire of one-sixteenth of an inch (1.6 mm) to tie the rebar. Rebar steel material typically has high carbon content, which makes them fragile after the thermal stress of uncontrolled welding. As a consequence, a structure with welded rebar may fail at a lower tension than what it was designed for.

FILL OUT THIS FORM TO GET YOUR QUOTE